Global OEM/ODM Partner for Hygiene Products

Professional One-Stop Customization Service

Customization Process

Communication Needs

You can share your core requirements with us regarding the product's features, specifications, target audience, packaging style, budget, delivery timeline, and other key aspects.

Product Confirmation

Organize the communication outcomes into a requirements list for mutual confirmation by both parties.

Select raw materials

Select core materials for disposable diapers (such as fluff pulp, superabsorbent polymer, nonwoven fabric, PE film, etc.) and packaging bag materials.

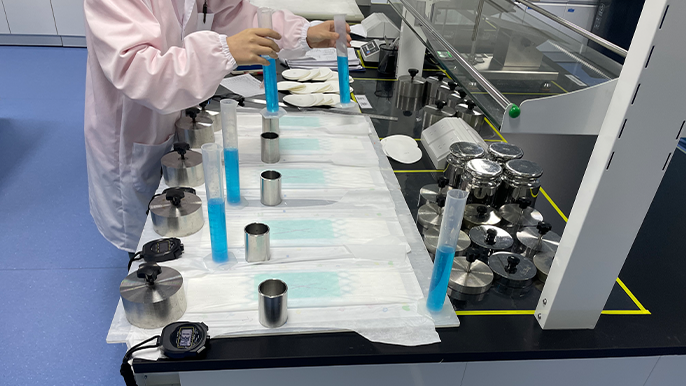

Produce samples and conduct testing

We produce samples based on requirements and raw material specifications while concurrently conducting performance tests (water absorption, breathability, leak resistance, softness, etc.), recording test data to ensure compliance with buyer specifications.

Sample delivery

Deliver the tested samples that meet customer requirements along with the inspection reports to the customer, assist in completing the physical verification of the samples, and address any questions regarding the test data.

Confirm the sample

After confirming the sample meets performance standards, simultaneously review the packaging design draft (logo, copy, dimensions, materials). Once both parties confirm accuracy, finalize the order and lock in production and packaging specifications.

Factory mass production

The factory develops production plans and manufactures products based on confirmed sample specifications, packaging standards, and required quantities.

Bulk Order Delivery

After mass production is completed, finished products undergo sampling inspection (in compliance with infant product safety standards). Upon passing inspection, products are packaged and shipped according to agreed-upon methods, with delivery lists and product inspection reports provided simultaneously.